Mold Engineering

In IMP we offer you our innovative mold design services. Our team of skilled engineers, with many years of experience in creating efficient molds, provides you with personalized service and guarantees a satisfactory customer experience that suits your needs and preferences, therefore minimizing mistakes and resulting in high-performing, cost effective molds.

Idea

In IMP we help bring your idea to reality. Our experienced team will work closely with you starting from product vision until the final design concept, we will aid you to identify your target audience and explore potential design concepts through sketches. Your final design concept will be presented in a 3d CAD model, which you can then send to potential clients.

Product Design

Following the creative phase of the process, which involves defining the specifications of your product, as well as, sketching and creating the visual image of your product, we will continue onto more concrete design processes which include: 3D CAD Design, Electrical and Mechanical Engineering, 3D CAD Development, FEA Analysis and Endurance Testing.

MoldFlow Analysis

MoldFlow Analysis is a very cost & time efficient injection mold design tool that allows us to minimize design errors in products and molds by mold simulation.

- Time to fill

- Process of filling

- Examination of plastic substance

- Examination of the thickness of the walls

- Examination of the feed system

- Pressure at V/P switchover

- Directions of defection: X, Y, and Z

- Volumetric shrinkage on average

- Air traps

- Weld lines

- Processing conditions

- Flow front temperature

- Overall Summary

DFM Report

This analysis report determines accurate tolerances in the mold and product designs and runs a number of examinations to ensure that there are no mistakes in the manufacturing process of the products/molds, thus reducing production cost and time of manufacture. It follows set guidelines for DFM practices.

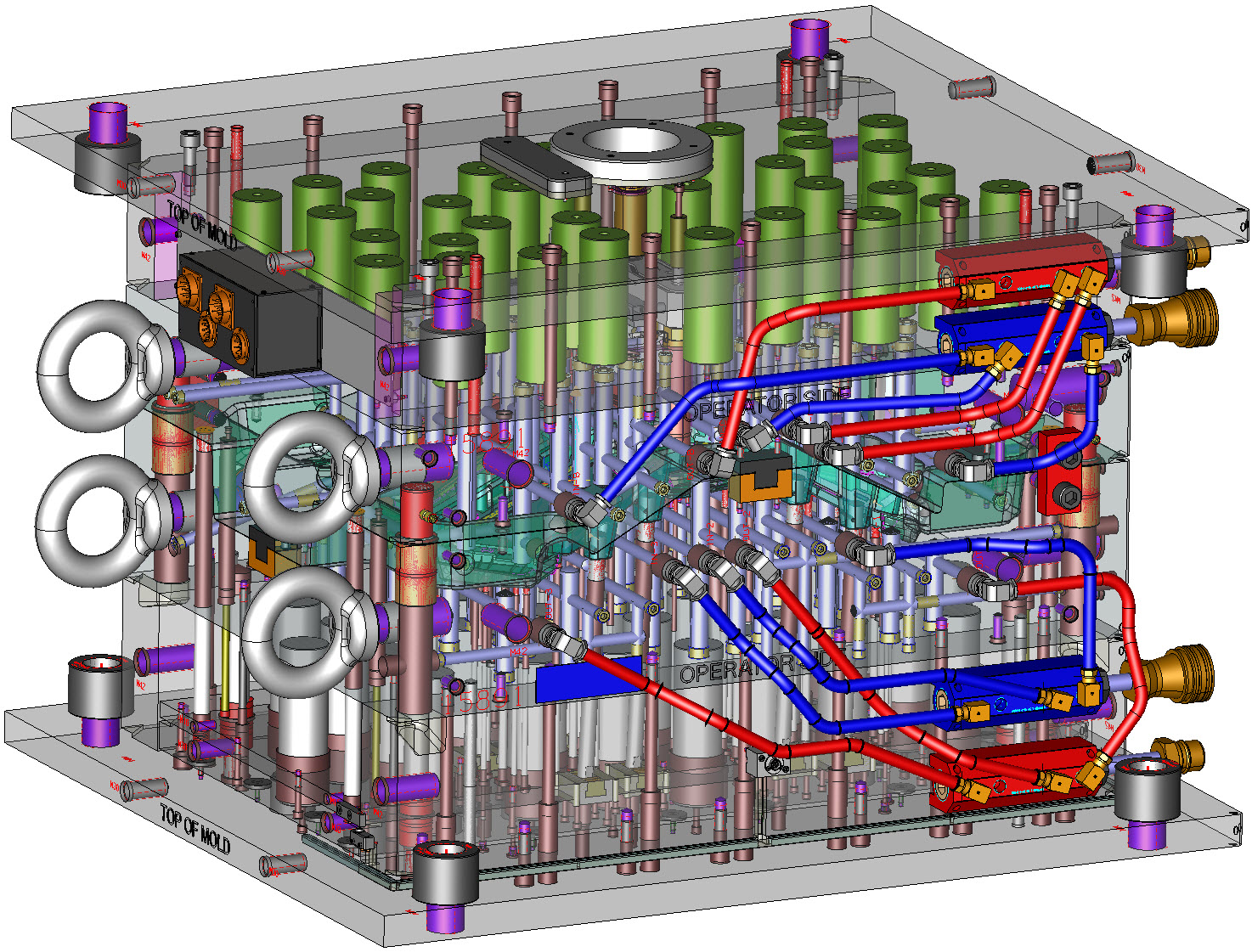

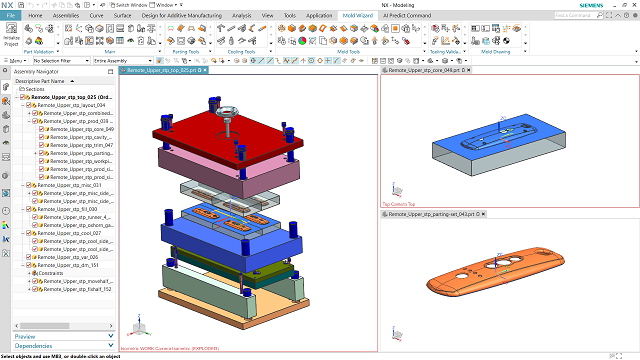

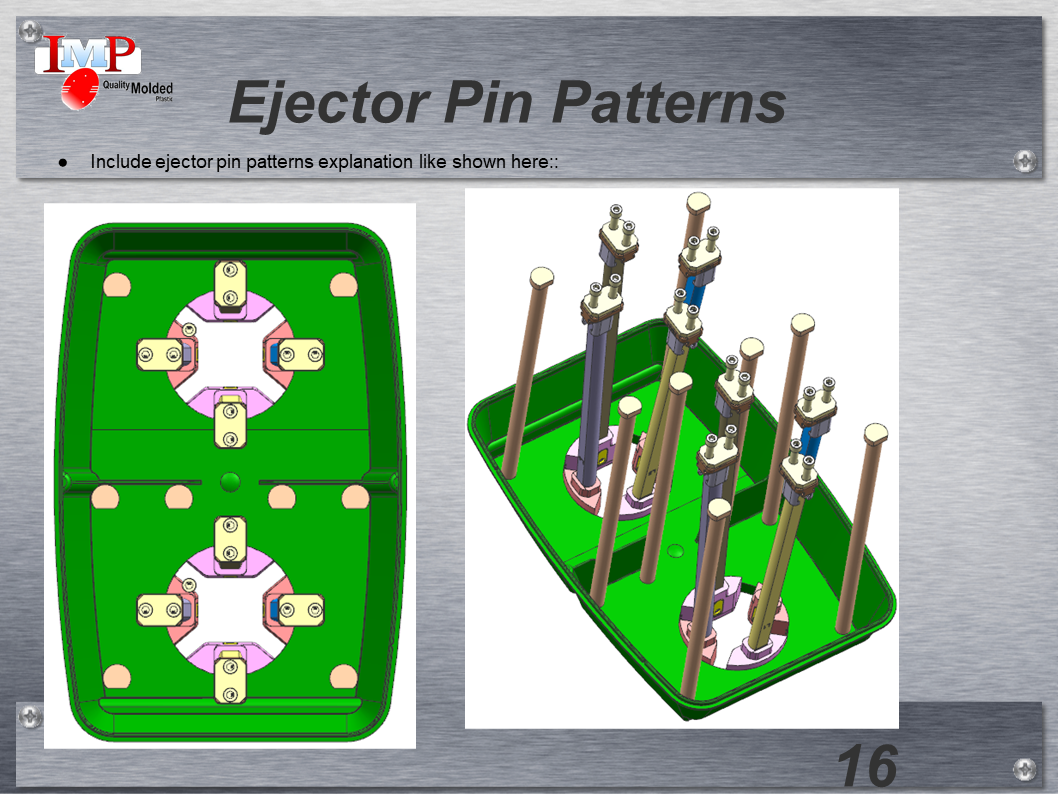

3D Mold Design

At IMP we use software technologies like Solidworks and AutoCAD to do 2D and 3D iterations of your products. With these tools we strive to help the client minimize errors in the design of the product and detect structural improvements that are needed.

Design Analysis

The last step in the process involves the communication between our clients and our highly trained engineers to reach a final mold design that satisfies the requirements of both parties. All analysis reports listed above will be included in the final mold evaluation report.

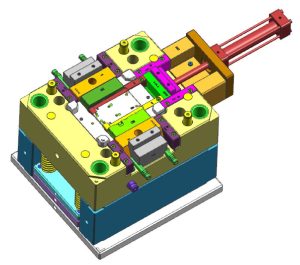

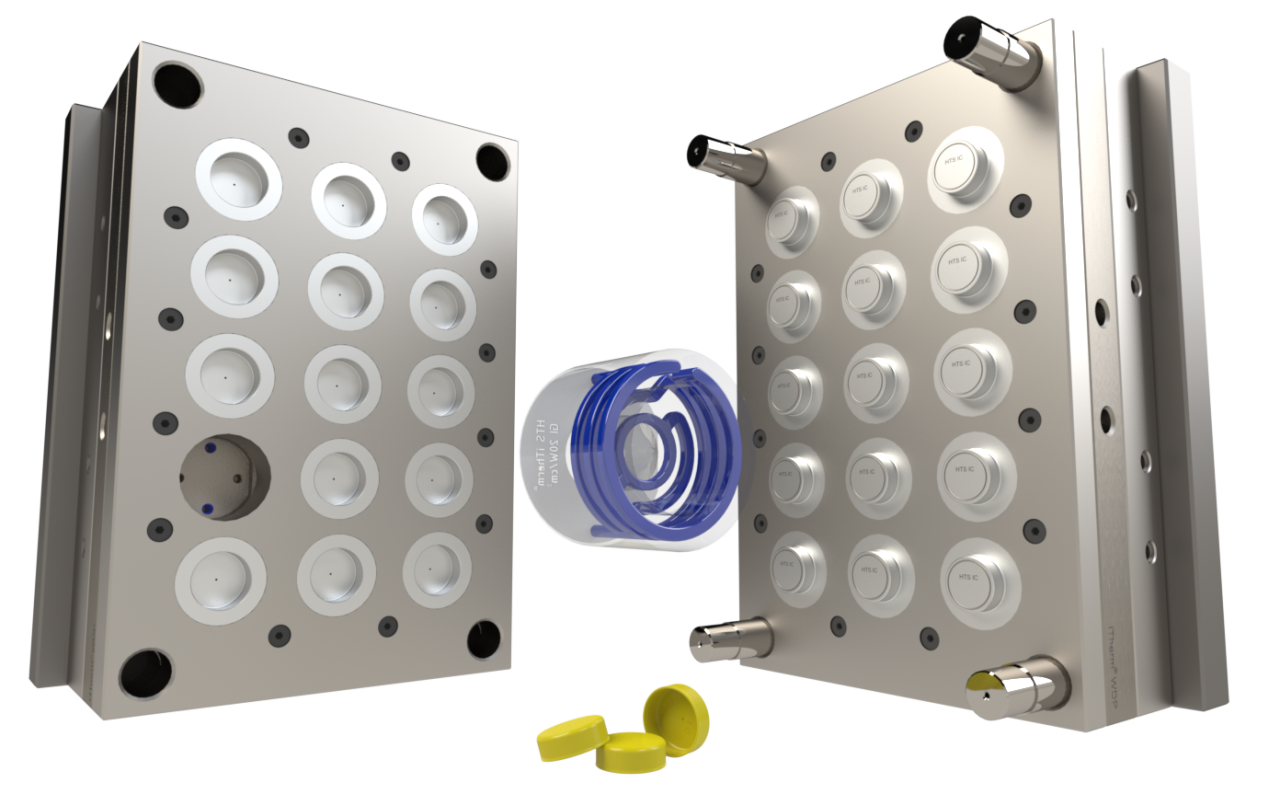

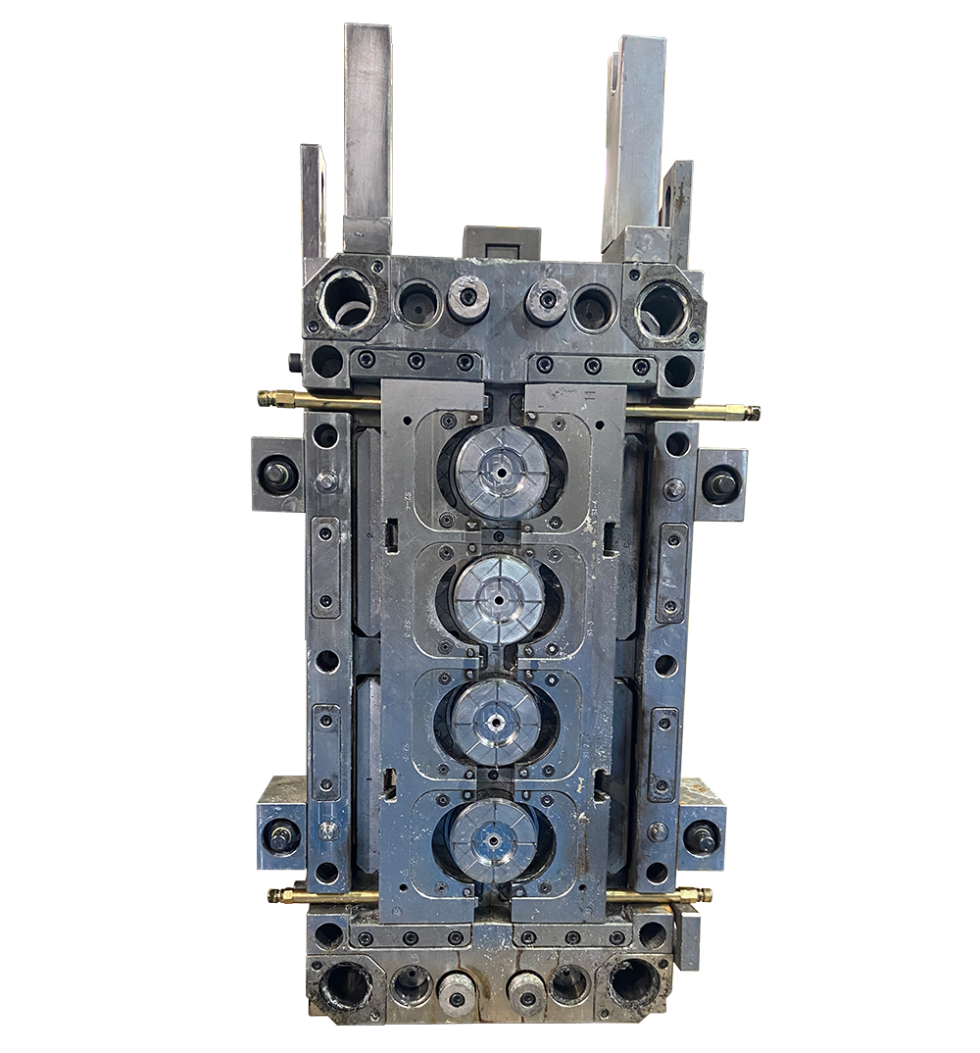

Tooling

In IMP we have the capabilities to quickly diagnose, replace or repair any injection mold components in our internal specialized tooling workshop. QUALIFIED TECHNICIANS AT IMP have ample experience in performing engineering changes for our clients to change fundamental aspects of the injected part.

Advantages of Tooling in IMP

- Internal specialized tooling workshop

- Experienced tooling technicians

- Exact mold dimensional requirements are met

- Premium materials

- Up to date equipment

- Fast delivery time

Plastic Injection Molding

- Over 20 years experiencie

- Over 150 plastic injection molding machines

Prototyping Advantages in IMP

- Variety of colors (custom colors available)

- 60+ material selection

- Boosts design optimization before mold and product manufacturing

- Reduces overall costs and production time

- Increases product suitability (prototypes can be tested)

- Low volume production is met

PROTOTYPING METHODS

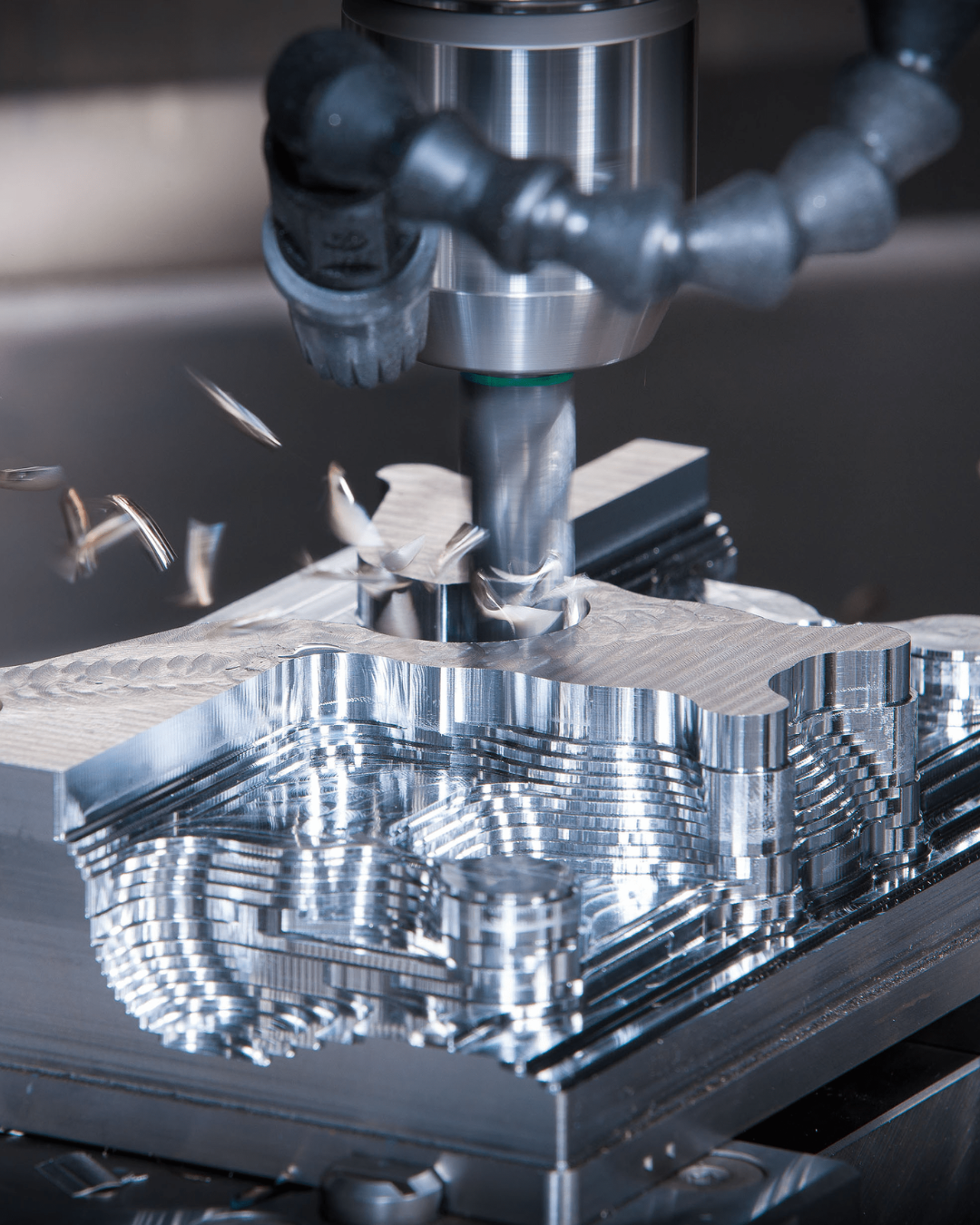

CNC Machining Prototyping

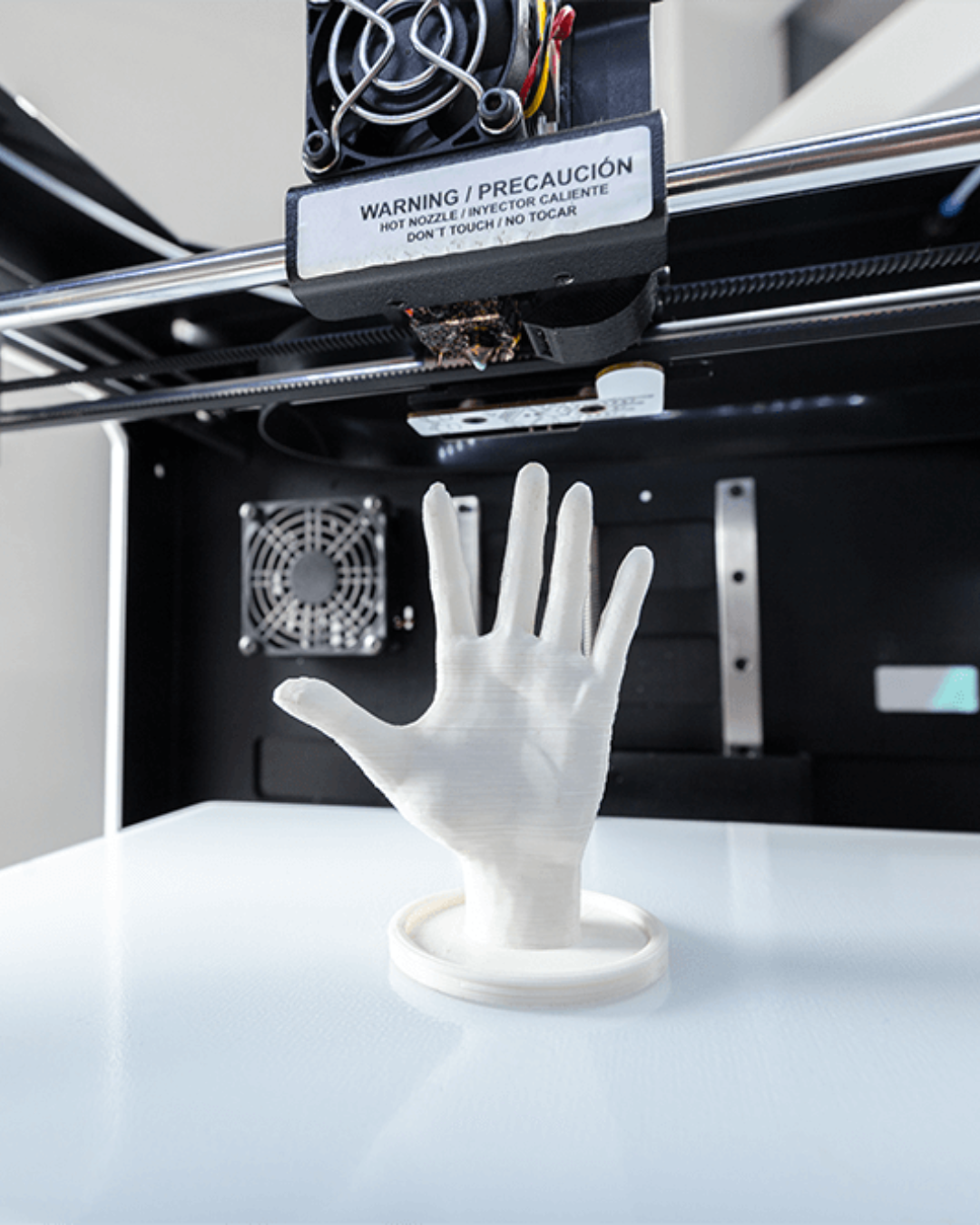

3D Printing

3D Printing

All the available tecnologies for 3D printing

None

SLA

Our stereolithography capabilities include a maximum build size of 145 X 145 X 175mm (xyz), a layer height of 50 to 100 micrometers (μm) and a fulfillment time of 2 to 3 days. SLA is great for parts that require smooth surface finish and a great level of accuracy. Ideal for injection molded like parts, functional prototypes and spare parts. Ask our representatives for material tolerances.

Available materials for our SLA printing process:

- Formlabs Clear Resin

- Formlabs Standard Resins

- Formlabs Flexible Resin

- Formlabs Elastic Resin

- Formlabs Tough Resin

- Formlabs Rigid 10K Resin

- Formlabs Durable Resin

- Formlabs Draft Resin

None

FDM

Our fused deposition modeling capabilities include a maximum build size of 200 X 200 X 200 mm (xyz), a layer height of 50 to 100 micrometers (μm) and a fulfillment time of 2 to 3 days. FDM is great for functional parts with superior mechanical properties and a high level of accuracy to the 3D model. Ask our representatives for material tolerances.

Available materials for our FDM printing process:

- PLA Filament

- TOUGH Filament

- PETG Filament

- NYLON Filament

- NYLON Carbon Fiber Filament

- ABS Filament

None

DMLS

Our direct metal laser sintering capabilities include a maximum build size of 350 x 350 x 350 mm (xyz). DMLS has high accuracy and can achieve up to 0.05mm of precision. Additionally, with this technology we can directly manufacture metal functional parts and vastly shorten the production process.

Available materials for our DMLS printing process include:

- Pure Metal Powder

- Alloy Metal Powder (Tooling Steel, Titanium, Aluminum, Copper, Stainless Steel, etc.)

Let’s Work Together

We will be honored to hear about your project and to help you execute it.